Control Systems

GSI Flo designs and builds electropneumatic control systems to customers’ needs. Customers specify limiting dimensions, size of reservoir, flow and pressure needed, and any special requirements like valves, surge needs, filtration, etc. GSI Flo uses these specifications to determine the proper equipment combination and the layout of the equipment. We build the system, test it, and deliver it within the time constraints specified.

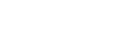

Electropneumatic Control System

This panel controls an automated manufacturing system for the assembly of industrial filter elements controlling numerous pneumatic actuators, two motor starters and a set of pneumatic grippers. It utilizes a Micrologix 1000 PLC, a SY valve manifold, a B4 two-hand-no-tie-down safety relay, and optical no-touch switches.

Photo switches detect the movement of plastic bottles down a pair of conveyors. Depending on which conveyor has bottles, pneumatic cylinder operated swing gates open and close to start and stop the transfer of bottles. A SLC500 modular PLC, a CCS pressure switch and a series of timer relays control the sequence. Spare PLC I/O, and the addition of spare pneumatic valves and relays allow for future growth.

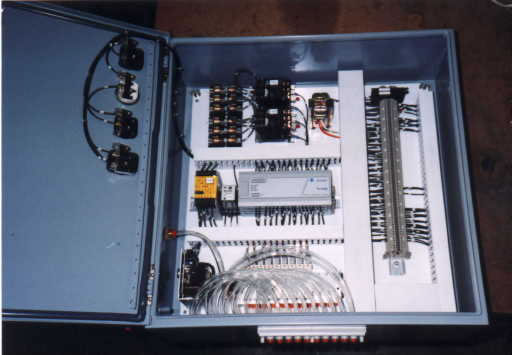

This control system uses photoeyes to detect boxes coming down a packaging line conveyor. Pneumatic actuated gates move the boxes in a particular sequence depending on box location. Digital timers are used to allow field selectable timing.

A Micrologix 1000 PLC controls the sequence. A stainless steel enclosure and 4X pushbuttons are used to maintain washdown capability and corrosion resistance.